1пЉО Background Introduction

Microspheres are small spherical entities formed by the dispersion or adsorption of drugs in a polymer matrix. The particle size typically ranges from 1 ќЉm to 250 ќЉm, with larger ones reaching over 800 ќЉm. In the medical field, injection microspheres, embolization microspheres, IVD (In Vitro Diagnostics) microspheres, and other derivatives of underlying technologies have extensive applications in areas such as drug preparation, delivery, and analysis and testing, promising a wide range of prospects.

Taking injection microspheres (microsphere formulations) and embolization microspheres as examples, injection microspheres gradually degrade after entering the body, allowing the drug to be released at a controlled rate, maintaining the blood drug concentration at the lesion site, thereby extending the drug’s half-life and achieving prolonged release. For patients, injection microspheres can significantly reduce the dosing frequency, improving compliance. Similarly, embolization microspheres fully utilize the sustained release effect of microspheres and are expected to be a future trend in super selective intra-arterial embolization development.

In the medical aesthetics industry, traditional medical aesthetics injection materials such as hyaluronic acid and collagen are gradually being replaced by regenerative injection materials that are safer and offer a better user experience. From 2016 to 2020, against the increasing popularity of “light medical aesthetics ” projects, the market size of injectable medical aesthetic procedures grew from 2.5 billion RMB to 4.7 billion RMB. It is estimated that by 2025, the market size of injectable medical aesthetic will reach 9.7 billion RMB, with a compound annual growth rate of 19.9%.

In the future, with the increasing enthusiasm of people for medical aesthetics and the growing demand for anti-aging and related products, biomedical microspheres will have vast development opportunities.

2пЉО Advantages of Biomedical Microsphere Formulations in the Medical Aesthetics Field

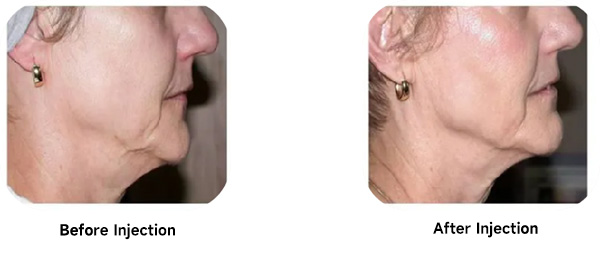

Poly-L-lactic acid (PLLA) microspheres are currently one of the most sought-after materials in the domestic medical aesthetics market. When PLLA microspheres penetrate the skin, they continuously stimulate fibroblast cells to synthesize collagen. The newly formed collagen gradually fills the volume loss areas, repairing the skin elasticity. This process fades facial wrinkles and depressions from the inside out and from shallow to deep, rejuvenating the skin and restoring youthful appearance, thereby achieving anti-aging effects.

Poly-L-lactic acid (PLLA) microspheres are regenerative materials that stimulate endogenous collagen regeneration. Collagen naturally fills the volume-deficient areas, resulting in a genuine and natural effect. Moreover, the degradation and metabolic pathways of the microspheres within the human body are apparent, preventing issues such as facial “puffiness” or stiffness caused by residual cross-linking agents.

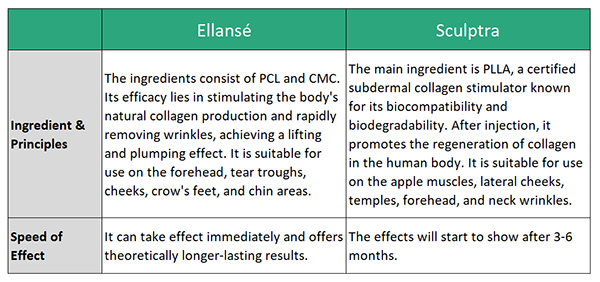

Poly ќµ-caprolactone (PCL) microspheres have widespread applications in the medical field, including drug delivery devices, sutures or adhesion barriers, tissue engineering scaffolds, drug release systems, and targeted delivery, among others. In medical aesthetics, products based on PCL can correct signs of facial aging, such as volume loss and sagging contours, by stimulating collagen production. They offer immediate and long-lasting natural results.

Currently, the highly popular “Ellans√©” and “Sculptra” have gained approval as new types of medical aesthetic devices around 2020, and their popularity in the market is gradually increasing. These two products primarily consist of PCL and PLLA respectively, catering to the diverse demands of consumers.

3. Overview of eSUNMed in the Microsphere Preparation Field

eSUNMed was established in 2022, leveraging the expertise of its parent company, Shenzhen Esun Industrial Co., Ltd., in the research and application of biodegradable polymer materials. With this advantage, eSUNMed possesses stable production capabilities for batch products in the field of microsphere preparation.

Currently, eSUNMed has the kilogram-scale preparation capability for homopolymers such as PCL, PLLA, and PDLA, as well as copolymers like PDLLA, PLGA, and PLCL. We have mastered the polymerization techniques for high molecular weight PLLA (intrinsic viscosity of 4.0 dL/g) and PCL (intrinsic viscosity of 2.0 dL/g). eSUNMed also possesses the ability to polymerize with different copolymer ratios and various end-group structures. Additionally, through purification processes, we can remove impurities from the polymers, ensuring the products meet the industry standards for implant-grade polylactic acid outlined in the “YY/T 0661-2017″ standard and the requirements for related pharmaceutical polymer excipients in the Chinese Pharmacopoeia.

In terms of hardware equipment, eSUNMed is equipped with precision testing instruments such as Infrared Spectroscopy (IR), Differential Scanning Calorimetry (DSC), Gas Chromatography (GC), High-Performance Liquid Chromatography (HPLC), Gel Permeation Chromatography (GPC), and Polarimeter. These instruments are used to characterize the structure, purity, molecular weight, thermodynamic properties, solvent and monomer residues of materials.

As for product packaging, eSUNMed utilizes double-layer vacuum packaging for our products. Sterile products can be provided if needed.

4. Introduction to eSUNMed Microsphere Preparation Technology and Processes

Through research on cutting-edge technologies such as membrane emulsification and microfluidics, eSUNMed can produce size-controlled and uniformly sized droplets. Through studies on droplet solidification processes, we manufacture smooth-surfaced, highly spherical, blank microspheres of PLLA, PCL, PLGA, etc., with controllable D50 within the range of 10-100 ќЉm. Unique size grading processes narrow the particle size distribution, achieving a span value of less than 0.7.¬†

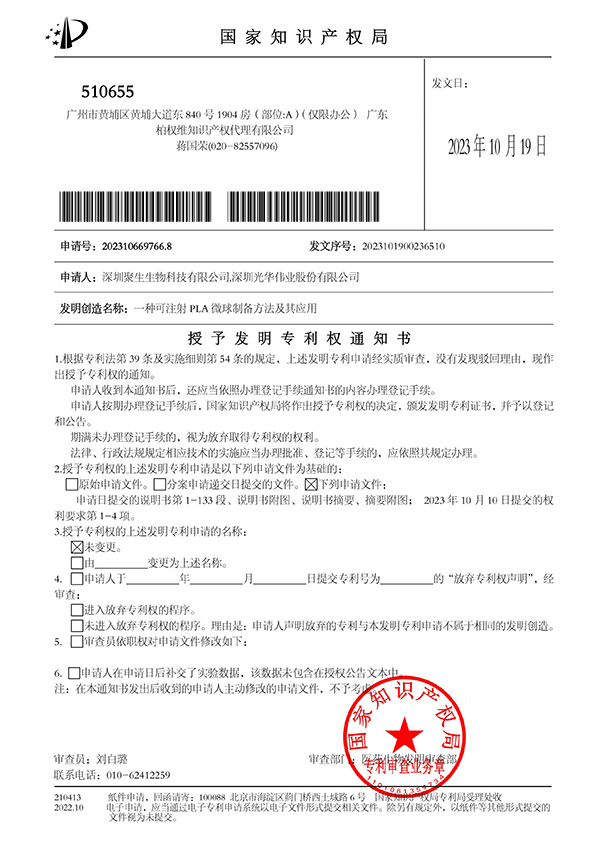

5. Overview of eSUNMedвАЩs Patents

Regarding patent technology, eSUNMed has relevant patents in monomer synthesis purification, polymer synthesis, material processing, and applications. These include patents related to monomer purification, medical-grade, non-toxic, efficient catalysts, microsphere preparation, and polylactic acid implant membranes, among others. These patents reflect the company’s comprehensive technical layout in the entire process of medical implant biomaterials.

Patent Granted: “A Method for Injectable PLA Microsphere Preparation and Its Application”

6. eSUNMed Microsphere Processing Services

eSUNMed is primarily dedicated to the development and application of biomedical polymer materials. Currently, we offer customized microsphere processing services tailored to user requirements. On one hand, eSUNMed can provide customers with various medical-grade raw materials, such as PLA, PDLLA, PCL, PLGA, PLCL, etc., with different molecular weights. On the other hand, we can customize solid microspheres of these polymers with diameters ranging from 20-100ќЉm based on customer demands.

eSUNMed possesses nearly 400гО° class 100,000 cleanrooms and 100гО° class 10,000 purification laboratories. These facilities meet the standard GMP (Good Manufacturing Practice) requirements for producing pharmaceutical excipients and sterile medical devices, aligning with the industry standards for biomedical polymer materials. Additionally, eSUNMed has various advanced equipment, providing stable support for product research, development, production, and application.¬†

Microsphere technology represents an intersection of various cutting-edge disciplines, such as materials science, polymer technology, pharmaceutical engineering, and microelectronics. It holds significant advantages in clinical and multiple related fields, presenting vast opportunities for future development. In the medical aesthetics industry, with the trend towards industrial standardization and increased consumer spending, this industry is becoming a new hotspot for consumption and holds great potential. eSUNMed welcomes research institutions or businesses needing to contact us for customized products or the development of new applications!