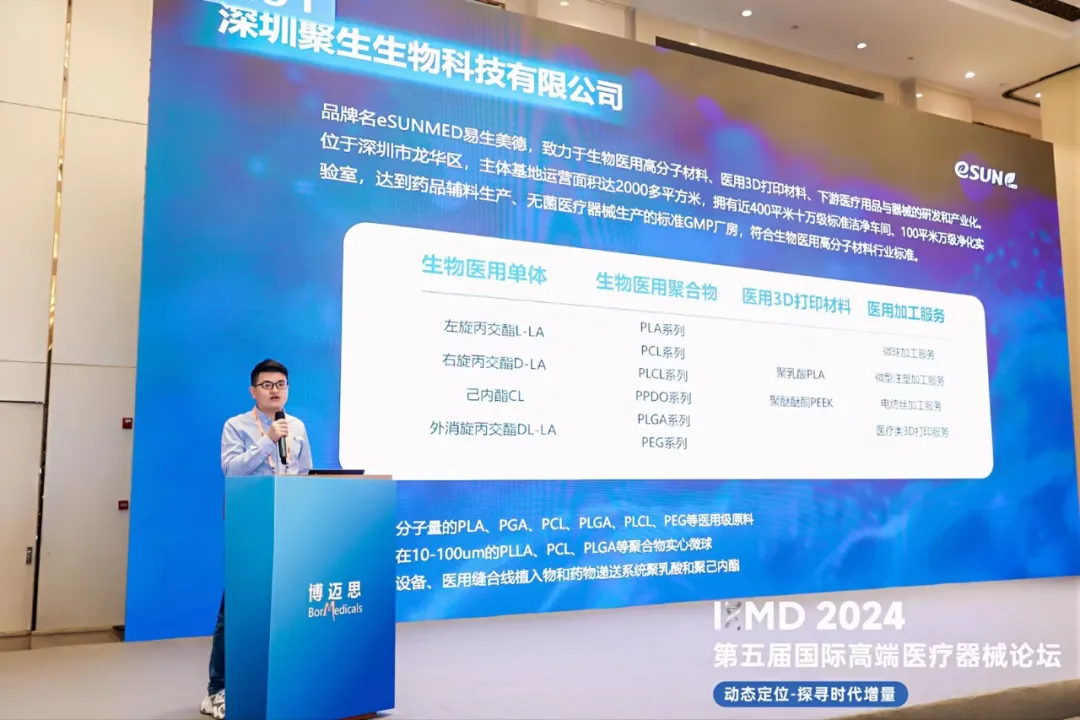

eSUNMedô was invited to participate in the “IHMD 2024: 5th International High-End Medical Device Forum” held in Shanghai from November 6 to 7, 2024. During the conference, the company delivered an impressive presentation on its research achievements, applications, and future development trends in the field of high-end medical devices.

Biomedical polymers are a class of high-molecular-weight materials used in the medical field, primarily for the fabrication of internal organs, external devices, drug formulations, and medical instruments.

Biomedical Polymers

- PLA Series:

Polylactic Acid (PLA) is a common environmentally friendly, fully biodegradable material. In aesthetic medicine, PLA microspheres exhibit excellent biocompatibility and biodegradability. They are used as injectable fillers to improve skin issues and degrade naturally over time without long-term impact. Through modification, PLA microspheres can achieve diverse performance properties. In drug delivery and tissue engineering, biodegradable drug-loaded microspheres enable sustained release, prolonging drug half-life, reducing administration frequency, and improving compliance. - PCL Series:

Polycaprolactone (PCL) is a flexible material with excellent processability, outstanding properties, high crystallinity, and slow degradation rates. PCL microspheres have widespread medical applications, including drug delivery systems, sutures, adhesion barriers, tissue engineering scaffolds, controlled drug release, and targeted delivery. In aesthetic medicine, PCL-based products stimulate collagen production to correct signs of facial aging, such as volume loss and contour sagging, offering both immediate and lasting natural results. - PLCL Series:

Poly(L-lactide-co-öç-caprolactone) (PLCL), also known as co-modified PLA (eCo-PLA), is a copolymer material made from L-lactide and other monomers. By copolymerization, PLCL improves PLA’s melting point, transparency, toughness, and heat resistance, addressing the limitations of blending modifications. It allows tuning of crystallinity, biodegradability, and mechanical properties, providing good flexibility and elasticity for applications in biomaterials, 3D printing, and biodegradable products. - PPDO Series:

Poly-p-dioxanone (PPDO) is a high-performance bioresorbable polymer with extensive medical applications. It features excellent biocompatibility and biodegradability, gradually degrading and being absorbed in the body, thus avoiding the need for secondary surgeries. PPDO is widely used for sutures, patches, and internal fixation devices, effectively promoting tissue healing and repair. Its unique physical and chemical properties also provide superior mechanical performance and stability for diverse medical needs. - PLGA Series:

Poly(lactide-co-glycolide) (PLGA) is a copolymer synthesized from lactide and glycolide monomers. It is a biodegradable biomedical polymer with excellent biocompatibility, complete degradability in the body, and adjustable degradation rates. PLGA is extensively used in the pharmaceutical industry for medical sutures, controlled drug release systems, tissue engineering, and bone fixation materials. - PEG Series:

Polyethylene Glycol (PEG) is a high-molecular-weight compound polymerized from ethylene oxide, ethylene glycol, and water. With outstanding water solubility, lubricity, chemical stability, and biocompatibility, PEG finds extensive applications across pharmaceuticals, personal care, and chemical industries. In medicine, PEG is used as a drug modifier to enhance water solubility, reduce immunogenicity, and prolong half-life. PEG also serves as a raw material for soft capsules, ointments, and suppositories and as a solvent, solubilizer, and lubricant, significantly improving product quality and manufacturing efficiency.

Polymeric materials have broad and diverse applications in biomedicine, including but not limited to the manufacture of artificial organs using 3D printing technology, drug delivery systems, tissue engineering and repair, as well as medical aesthetics in various key areas.

Medical 3D Printing Materials

- Polylactic Acid (PLA):

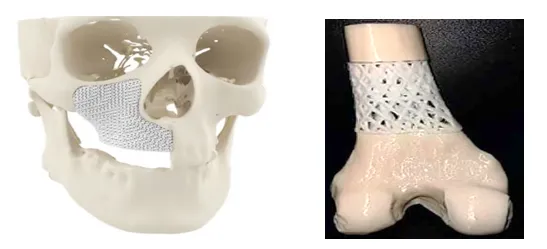

PLA medical filaments hold significant value in applications such as 3D printing maxillofacial/cranial bone repair implants, porous cartilage repair scaffolds, and vascular stents. Their excellent bioabsorbability, high strength and ductility, and good biocompatibility make PLA 3D printing filaments widely used in the medical field. Examples include absorbable maxillofacial bone repair implants and porous bone repair scaffolds.

- Polyetheretherketone (PEEK):

As a novel high-strength engineering plastic, PEEK exhibits outstanding high-temperature resistance, self-lubricating properties, and chemical stability. A key advantage of PEEK is its excellent biocompatibility. Compared to metal materials, PEEK-based implants have an elastic modulus closer to that of human bone, enabling their mechanical properties to meet the demands of normal human activity. PEEK is an ideal material for orthopedic implants and is used to manufacture medical implants such as scaffolds, connecting plates, sternal fixation bands, and intervertebral cages.

Medical Processing Services

- Microsphere Processing Services

- Drug Carriers and Release: Microspheres can serve as drug carriers to achieve controlled release and targeted drug delivery, improving the bioavailability and therapeutic effect of drugs. Common drug carrier microspheres include PLGA, PCL, and other biodegradable polymer microspheres. These microspheres can carry biologically active substances such as peptides and proteins, and the drug release rate can be controlled by adjusting the degradation rate of the microspheres.

- Medical Aesthetic and Skin Care: Microspheres are widely used in medical aesthetics for filling and skin repair. Materials like PLLA and PCL microspheres are used as fillers to stimulate collagen regeneration, improve skin laxity, wrinkles, and other concerns.

- Tissue Engineering and Regenerative Medicine: In tissue engineering, microspheres are used as materials for creating scaffolds, providing three-dimensional space and a metabolic environment for cell proliferation. By adjusting parameters like shape, size, and porosity, different structures and functional tissue engineering scaffolds can be created.

- Micro Injection Molding Services

- Medical Devices and Tools: This service manufactures precision medical devices and tools such as microcatheters, endoscope parts, and surgical instruments. These products require high precision, good biocompatibility, and durability to ensure the safety and effectiveness of surgeries.

- Biocompatible Implants: Micro injection molding technology is used to manufacture biocompatible implants such as bone screws, bone plates, and dental implants. These implants need to be compatible with human tissue and maintain their structure and function over the long term.

- Drug Delivery Systems: Micro injection molding technology is also used to produce micro drug delivery systems such as microneedles and micro pumps. These systems can precisely control the release time and dosage of drugs, improving the efficacy and safety of treatments.

- Electrospinning Processing Services

- Tissue Engineering: Electrospun nanofibers are considered excellent materials for tissue engineering due to their good biocompatibility, controllable mechanical properties, and characteristics similar to natural extracellular matrices. Electrospun nanofibers are already being researched and applied in various tissue engineering fields such as skin, blood vessels, heart, nerves, and bone tissue.

- Wound Dressings: Electrospun nanofibers, with their large surface area, good mechanical strength, and resemblance to natural extracellular matrices, show great potential in wound healing. As wound healing materials, electrospun nanofiber membranes not only provide excellent waterproof and breathable properties, but they can also carry drugs to inhibit bacteria and promote cell growth.

- Filtration: The electrospun nanofibersã three-dimensional interwoven structure, large surface area, porous fibers, and strong adsorption make them excellent for filtration, barrier, and adhesion applications. When made into adsorbent filter materials, they can be used for sub-micron particle filtration and as barrier materials that block the migration of certain particles and ions.

- Medical 3D Printing Services

- Personalized Medical Devices and Implants: 3D printing technology can create customized prosthetics and orthotics based on the patient’s specific anatomical structure and needs, providing better comfort and functionality. High-quality, precise orthopedic implants such as bones and joints can also be produced. These implants match the patient’s anatomy closely, reducing surgery time and post-surgery complications.

- Surgical Planning and Simulation: By 3D printing models of a patient’s organs or lesions, surgeons can perform detailed surgical planning and simulation, improving the likelihood of surgery success. 3D printed surgical guides can help surgeons with precise localization during surgery, ensuring cutting and implant accuracy and lowering surgical risks.

- Tissue Engineering and Regenerative Medicine: 3D printing technology enables the production of biomimetic scaffolds that support cell growth and tissue regeneration. These scaffolds can facilitate tissue repair and regeneration, helping address organ transplantation issues such as donor shortages.

eSUNMedô has received over ten invention patent authorizations and four medical device main document registrations. These technologies are widely applied in the medical device sector (absorbable bone screws, bone plates, bone rods, etc.), medical aesthetics (absorbable microspheres, sutures, etc.), cardiovascular applications (absorbable stents, occluders, etc.), drug delivery (drug-loaded microspheres, excipients, etc.), and other areas (medical 3D printing, electrospinning, micro injection molding, etc.).

eSUNMED is dedicated to the research, development, and commercialization of biomedical polymers, medical 3D printing materials, and downstream medical products and devices. Located in Longhua District, Shenzhen, the company’s primary base covers over 2,000 square meters, featuring nearly 400 square meters of class 100,000 standard cleanrooms, and a 100-square-meter class 10,000 purification laboratory. The facilities meet the GMP standards for pharmaceutical excipient production and sterile medical device manufacturing, complying with the industry standards for biomedical polymer materials.

eSUNMED’s primary products and services include: offering various molecular weights of PLA, PGA, PCL, PLGA, PLCL, PEG, and other medical-grade raw materials, customizing polymer solid microspheres such as PLLA, PCL, PLGA with particle sizes ranging from 10 to 100 microns, as well as designing medical devices, sutures, implants, and drug delivery systems based on polylactic acid (PLA) and polycaprolactone (PCL).

eSUNMEDô warmly invites research institutions and enterprises with related needs to contact us for product customization or the development of new application fields!