On September 11, the 2024 International Medical Aesthetics Device Conference was held in Shenzhen!ô eSUNMed Biotechnology (Shenzhen)Co.,Ltd. was invited to participate in this event, where the company’s Technical Director delivered a keynote presentation titled “Innovative Applications and Insights on Biodegradable Biomedical Materials in High-End Medical Aesthetics.”

The “beauty economy” in the new era provides fresh momentum for the development of the medical aesthetics industry, which is becoming a new consumption hotspot. Traditional injection materials, such as hyaluronic acid and collagen, are gradually being replaced by regenerative injectable materials that offer greater safety and superior user experiences. Thanks to their advantageous properties, biodegradable medical injection materials have broad development prospects.

For instance, regenerative injection products like Youth Needleô and Baby Face Needleô are gaining popularity in the market. The main components of these two products are polycaprolactone (PCL) and poly-L-lactic acid (PLLA), respectively. Biodegradable polyester materials have been widely recognized for their market performance.

I. Characteristics and Applications of Degradable Polyester Materials

Degradable polyester materials possess several advantageous properties, including abundant raw material sources, high design flexibility, excellent formability, superior mechanical performance, and outstanding biocompatibility. These characteristics make them widely applicable in the biomedical field, including cardiovascular interventions, neurosurgery, orthopedics and sports medicine, plastic and maxillofacial surgery, otolaryngology, aesthetic medicine, general surgery, oncology treatments, and regenerative medicine.

Characteristics of Degradable Polyester Materials

- Degradability

- Biocompatibility

- Superior Processability

Degradable polyesters can be fabricated into diverse shapes and forms, including filaments, 3D printing materials, tubes, microspheres, porous scaffolds, and medical devices. - High Design Flexibility

- Chemical Design: The degradation cycles, mechanical properties, and hydrophilicity/hydrophobicity can be controlled by varying the types and ratios of copolymerized monomers.

- Molecular Structure: Adjusting polymer molecular weight, distribution width, chain-end modification, block, branched, crosslinked, or hyperbranched structures allows precise regulation of material performance.

- Aggregate Structure: Through techniques such as polymer orientation and crystallinity control, degradation rates and mechanical properties can be fine-tuned.

- Blending: Blending enables the design of heterogeneous systems with specific structural characteristics for enhanced material performance.

- Multidimensional Design: Rationally designing the monomer composition, polymer molecular structure, condensed state structures, and heterogeneous morphological characteristics enables precise performance control over degradable polyesters.

Innovative Applications of Degradable Polyester Materials in the Aesthetic Medicine Industry

In the future field of regenerative aesthetic medicine, continuous material innovation and application will drive the iterative advancement of minimally invasive aesthetic products. This includes multiscale design and modification of degradable polyester materials, the development of degradable porous microspheres, and injectable degradable materials, all of which hold significant potential for applications in regenerative injectables.

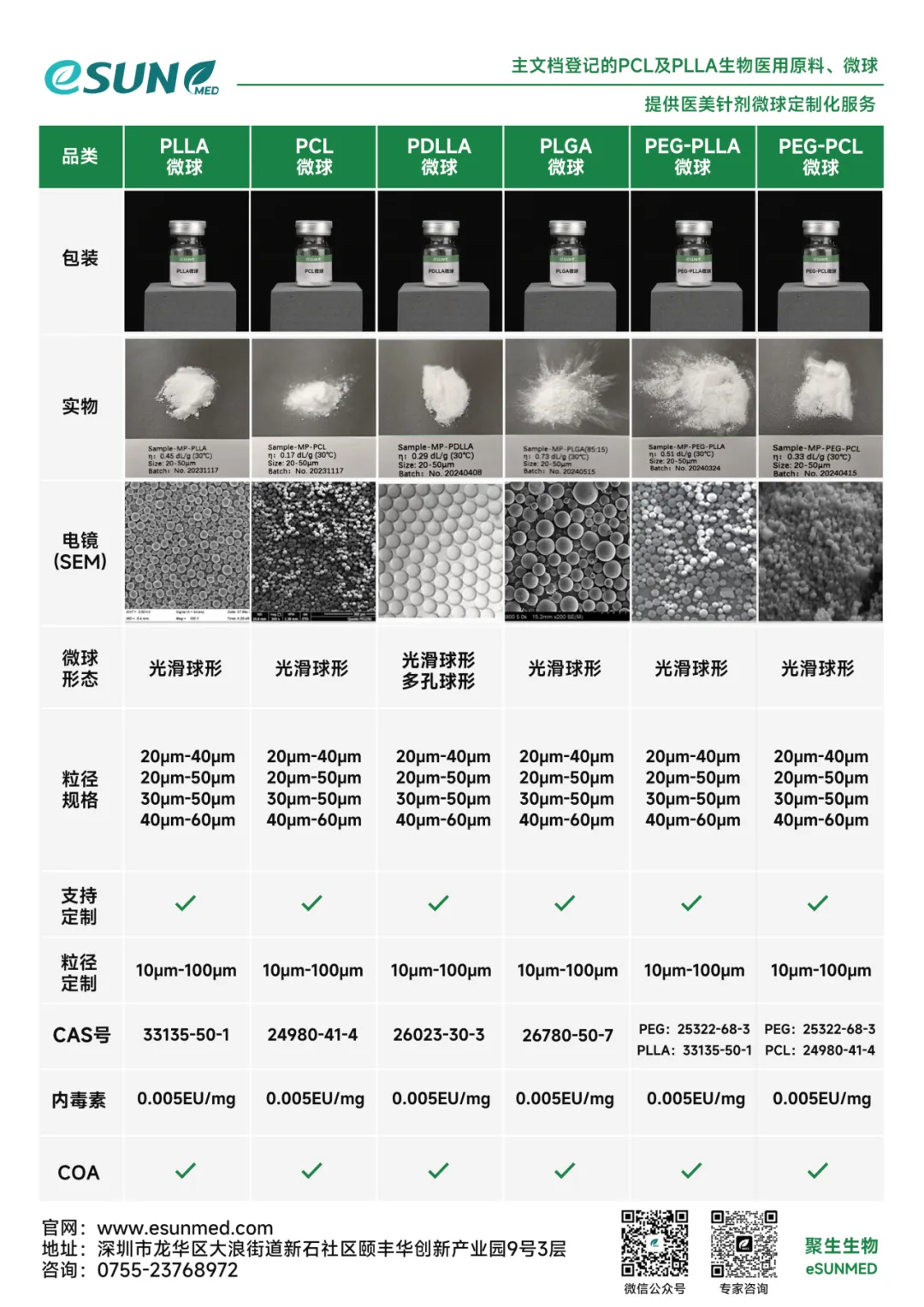

II. Introduction to Shenzhen eSUNMEDãs Products

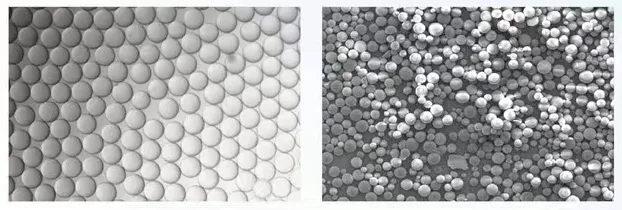

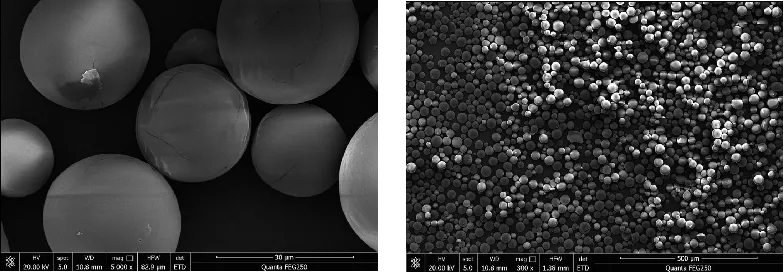

eSUNMed Biotechnology (Shenzhen)Co.,Ltd.(brand name ãeSUNMEDã) is primarily focused on the development and application of biomedical polymer materials. Currently, eSUNMED offers a variety of medical-grade raw materials, such as PLA and PCL, with different molecular weights. Additionally, the company can customize solid polymer microspheres with diameters ranging from 10-100 ö¥m based on customer requirements.

Four flagship products have successfully obtained Master File Registration Certificates: implant-grade PLLA polymers and microspheres, as well as PCL polymers and microspheres, have all completed master file registrations. Moving forward,ô eSUNMED will continue to refine the registration of other promising products, including PDLLA raw materials and microspheres, as well as PEG copolymers and microspheres.

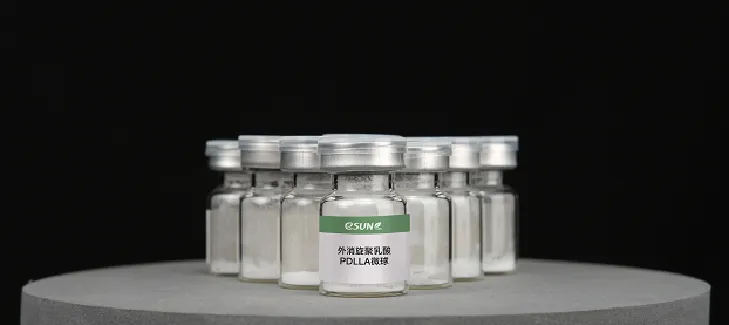

eSUNMED PDLLA Microspheres

PDLLA materials processed into 20ã50 ö¥m microspheres are high-performance subcutaneous stimulatory fillers with characteristics similar to PLLA microspheres but with a faster degradation rate both in vivo and in vitro. Overall, PDLLA microspheres, as a new type of facial filler, offer excellent biocompatibility, biodegradability, and the ability to stimulate collagen regeneration during degradation. Currently, aesthetic filler products based on PDLLA microspheres have been widely applied in clinical settings.

eSUNMED PEG-PLLA Microspheres

PEG-PLLA microspheres are amphiphilic polymer microspheres combining the characteristics of polyethylene glycol (PEG) and poly-L-lactic acid (PLLA). They exhibit excellent biocompatibility, biodegradability, and biosafety. These microspheres demonstrate exceptional potential in drug delivery, tissue engineering, and regenerative medicine. Currently, aesthetic filler products based on PEG-PLLA microspheres have been applied in clinical practice.

eSUNMED PCL Microspheres

eSUNMED Polycaprolactone (PCL) microspheres are biodegradable medical materials with excellent biocompatibility. These microspheres are spherical particles made from polycaprolactone (PCL) using various fabrication methods. Due to their extended degradation time, they are frequently utilized in the development of sustained-release drug formulations, making them particularly suitable for microsphere-based drug carriers. Additionally, PCL microspheres and their composite materials are also promising candidates for bone tissue engineering scaffolds.

eSUNMED Introduction

Established in 2022, eSUNMED leverages the advantages of its parent company, Shenzhen Esun Industrial Co., Ltd., in the R&D and application of biodegradable polymer materials. eSUNMED boasts a stable capability for large-scale production of polymer materials.

Currently, eSUNMED has the capacity to produce kilogram-level quantities of PCL, PLLA, PDLA homopolymers, and PDLLA, PLGA, PLCL copolymers. The company has mastered polymerization technologies for high-molecular-weight PLLA (intrinsic viscosity of 4.0 dL/g) and PCL (intrinsic viscosity of 2.0 dL/g), and can customize polymers with varying copolymer ratios and terminal group structures. Furthermore, through purification processes, the company removes impurities from polymers to meet the implant-grade polylactic acid industry standards outlined in YY/T 0661-2017 and the requirements of the Chinese Pharmacopoeia for related pharmaceutical polymer excipients.

We warmly welcome inquiries from research institutions, enterprises, and organizations. Collaborate with us to customize products or develop new applications tailored to your needs!