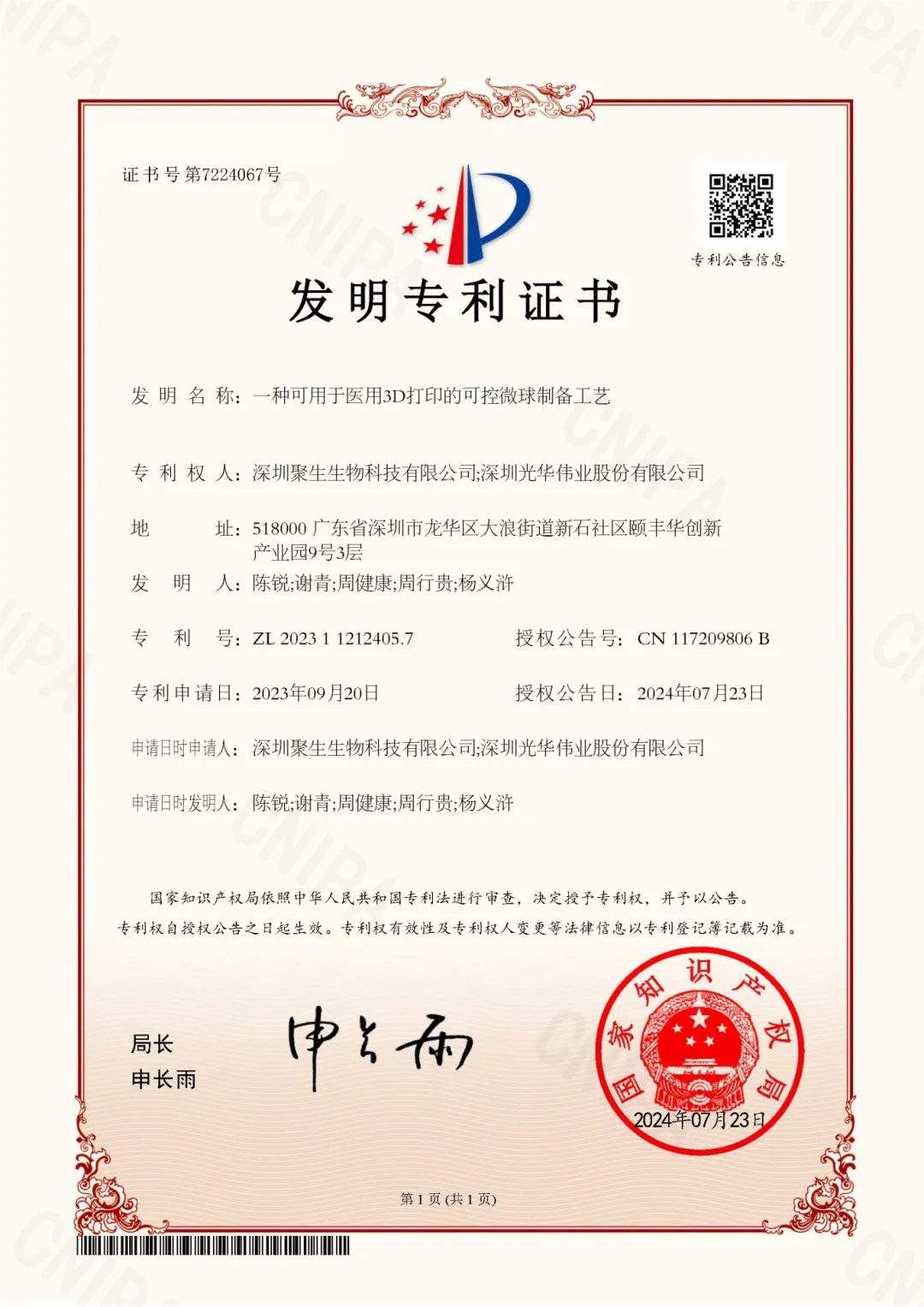

On July 23, 2024, the “Controllable Microsphere Preparation Process for Medical 3D Printing” independently developed byô Shenzhen Esun Industrial Co., Ltd. and its subsidiaryô eSUNMed Biotechnology (Shenzhen)Co.,Ltd. officially passed the review by the National Intellectual Property Administration and was granted a national invention patent. This invention aims to provide a controllable microsphere preparation process for medical 3D printing, enabling the control of microsphere particle size and biodegradation rate.

On May 31,ô eSUNMed was granted the patent for “A Medical Biodegradable Microsphere and Its Preparation Process.” Currently,ô eSUNMed has achieved a comprehensive technological layout for the entire process of medical implant biomaterials. The company holds relevant patented technologies in areas such as monomer synthesis and purification, polymer synthesis, material processing, and application. These include patents for monomer purification, medical non-toxic high-efficiency catalysts, microsphere preparation, and PLA implant membrane patents, among others.

Microspheres are spherical particles formed by dispersing or adsorbing drugs in a polymer matrix, typically ranging in diameter from 1 micrometer to 300 micrometers. Medical biodegradable microspheres are usually made from biodegradable materials such as poly(lactic acid) (PLA), polycaprolactone (PCL), poly(lactic-co-glycolic acid) (PLGA), and others. These microspheres have broad applications across various fields, including pharmaceuticals, medical diagnostics, cosmetics, biotechnology, and chemicals.

For example, in the medical aesthetics field, PLA microspheres can be used as injectable fillers to enhance skin fullness, improve wrinkles, and reduce skin sagging. PLA microsphere fillers have better biodegradability, gradually decomposing and being metabolized, without causing long-lasting effects on the skin. Additionally, by modifying the microspheres, different properties can be imparted, such as varying degradation cycles.

The patent for “A Controllable Microsphere Preparation Process for Medical 3D Printing” provides an important method for preparing controllable microspheres in the field of medical 3D printing. This process is significant for medical applications such as drug-controlled release, tissue engineering, and regenerative medicine. By precisely controlling the characteristics of the microspheres, material performance can be optimized, treatment efficacy can be improved, and safer and more effective treatment options can be offered to patients.

eSUNMed, leveraging the advantages of its parent company Shenzhen Esun Industrial Co., Ltd.’s years of research and application in PLA, PCL, and related copolymers, is mainly focused on the development and application of biomedical polymer materials. Currently, Shenzhen Jusheng has achieved significant research progress in microsphere preparation and applications. Through research on advanced preparation technologies such as membrane emulsification and microfluidics, Shenzhen Jusheng is able to prepare size-controlled, uniform microspheres. By further refining the droplet solidification process, they are able to produce smooth-surfaced, well-rounded, and controllable microspheres made of PLLA, PCL, PLGA, and other materials. Special particle size grading techniques have been used to narrow the size distribution, achieving a span value of less than 0.7.

eSUNMed’s microsphere processing technology serves various fields, including medical aesthetics, drug release, targeted drug delivery, and cosmetics. The company offers customized microsphere services for medical aesthetic injectables, producing microspheres made from a variety of molecular weight polymers such as PLA, PGA, PCL, PLGA, PLCL, and PEG-polyester copolymers. The customizable particle size ranges from 10 to 100 ôçm, with processing tailored to meet specific user requirements.

The company operates nearly 400 square meters of 100,000-class standard cleanrooms and a 100-square-meter 10,000-class purification laboratory, in compliance with GMP standards for pharmaceutical excipients and sterile medical device production. This setup adheres to the industry standards for biomedical polymer materials. Additionally, the company is equipped with a range of advanced machinery to provide stable support for product R&D, production, and application.

Microsphere technology lies at the intersection of cutting-edge disciplines such as materials science, polymer technology, pharmaceutical engineering, and microelectronics. It demonstrates significant advantages in clinical applications and related fields, offering vast potential for future development.

In the medical aesthetics industry, as the sector moves towards greater standardization and consumer spending increases, this industry is rapidly becoming a new focal point of consumer demand, showing tremendous promise for growth.

eSUNMedô warmly welcomes R&D institutions or enterprises with specific needs to contact us for customized products or to explore new applications!