Laser sintering technology boasts advantages such as high precision, support-free printing, and a variety of printing materials, and has gradually become one of the manufacturing technologies widely applied in various fields. The polymer materials currently used in SLS printing mainly include nylon and its composites, TPU, PPS, PEEK, PP, etc. Compared to metal and ceramic materials, polymer materials have advantages such as lower molding temperatures, lower sintering laser power, and higher precision. At the same time, the diversity of polymer materials and their properties, as well as the application of various modification technologies, further enhance their application advantages in SLS 3D printing.

As 3D printing shifts from prototype manufacturing to the production of final-use parts, and with the increase in series production applications, polymer powder materials have a significant development prospect for the future.

This article will focus on the application of polylactic acid (PLA) powder materials in SLS 3D printing.

I. Analysis of the Characteristics of PLA Powder in SLS 3D Printing

Polylactic acid (PLA) is made from renewable plant resources and is known for its excellent biodegradability. It can ultimately decompose into carbon dioxide and water, making it an internationally recognized environmentally friendly material. It is hailed as a revolutionary new material in the field of polymer materials.

In the field of SLS 3D printing, polylactic acid (PLA) powder can form the custom, precise geometric shapes required for thermoforming and compression molds. Due to its performance characteristics, the printing process of PLA powder is safe and non-toxic. When applied to casting, there is no smoke or toxic gases produced, making it more carbon-efficient and environmentally friendly. Additionally, PLA powder has a lower melting temperature, which helps to reduce energy consumption.

Objectively speaking, PLA powder as a 3D printing material has its advantages, but it also has certain limitations in some professional fields. As a polymer material with good biocompatibility and biodegradability, the application of PLA powder materials in the medical direction can avoid shortcomings and highlight its advantages.

Firstly, polylactic acid (PLA) materials have good biocompatibility and can be used in tissue engineering, orthopedic repair materials, etc. The combination of PLA with SLS technology can solve problems such as the difficulty in customizing the shape and porous structure of bone scaffolds. PLA compounded with hydroxyapatite (HA) can be prepared into components such as bone plates through the SLS molding process, possessing good biocompatibility and osteoinductivity.

Additionally, the monomer of polylactic acid (PLA) contains a chiral atom, resulting in polymers with various stereoisomeric configurations, such as poly-L-lactic acid (PLLA), poly-D-lactic acid (PDLA), and poly-DL-lactic acid (PDLLA). Combining different compositions of PLA powder with SLS technology can endow the products with different properties, such as varying degradation cycles. PLLA and PDLA can form stereocomplexes through co-crystallization, which have higher melting points, better heat resistance, solvent resistance, and so on.

In summary, polylactic acid (PLA) powder, as a bio-based and biodegradable polymer material, is easy to use and has clear advantages. Its integration with SLS 3D printing technology will provide the industry with more environmentally friendly innovative solutions.

II. A Brief Introduction to the Application of PLA Powder in the Medical Field

Through SLS 3D printing technology, models of human tissues and organs with complex structures can be manufactured for testing, surgical simulation, and tissue engineering. It is used to print tissue engineering scaffolds, orthopedic implants, organs, etc.; the implants are absorbable and degradable inside the body, allowing for customized, personalized, and precise printing models, reducing production time and costs, with a broad application prospect in the medical field.

1.Custom Medical Instruments and Equipment

SLS can be used to manufacture medical instruments and equipment, such as surgical tools, support prostheses, etc. Because SLS technology can create complex geometric shapes in a single step, it allows for the production of personalized products that are tailored to specific patients, providing better adaptability and comfort.

2.Bionic Tissue and Organ Models

SLS technology can be used to create bionic tissue and organ models for medical research, teaching, and surgical planning. These models provide doctors with a more intuitive understanding of the patient’s condition and assist in surgical planning and training.

3.Biomedical Material Research

In addition to directly manufacturing medical products, SLS can also be used for the research and development of biomedical materials. SLS technology can produce biomaterials with specific structures and properties for use in fields such as tissue engineering and drug delivery.

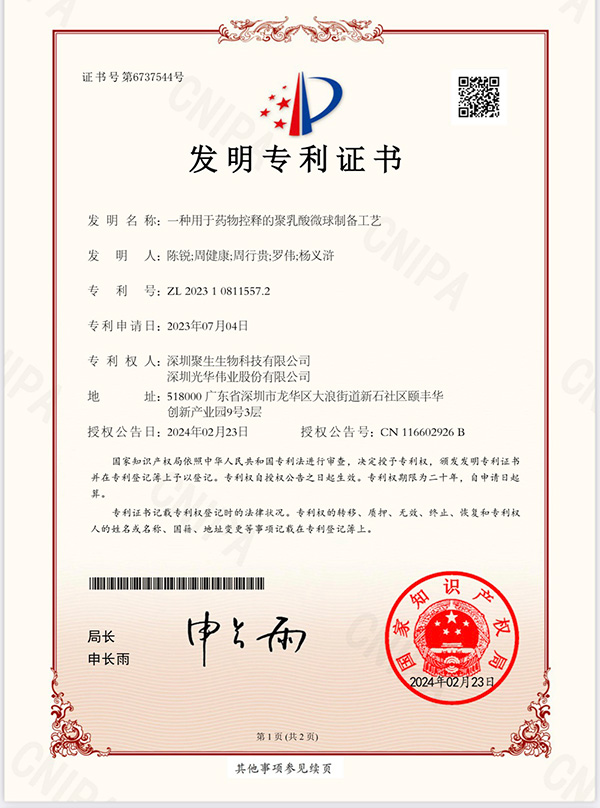

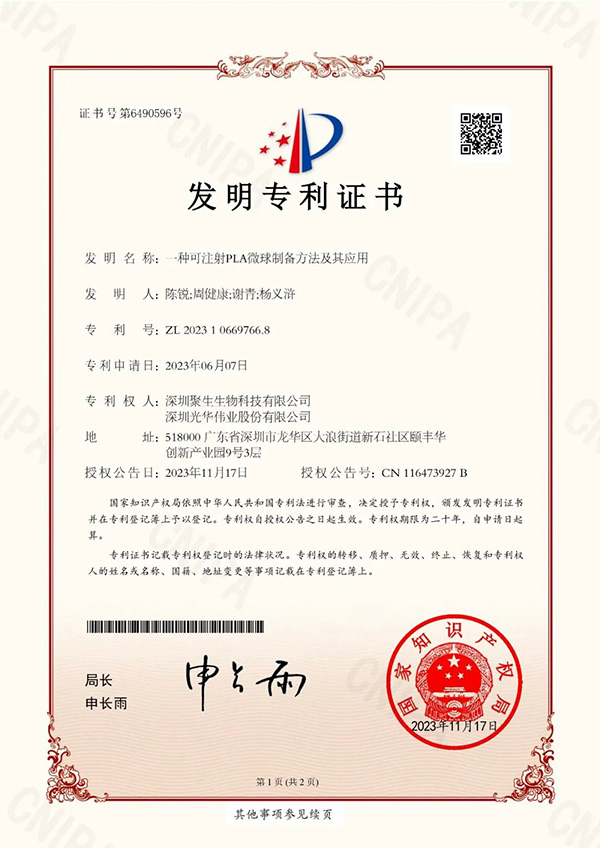

III. About eSUNMED

eSUNMED is primarily dedicated to the development and application of biomedical polymer materials. Currently, eSUNMED can provide customized microsphere processing services according to user needs. On one hand, it can supply customers with medical-grade raw materials of various molecular weights such as PLA, PDLLA, PCL, PLGA, PLCL, etc. Additionally, it can also customize solid microspheres of the aforementioned polymers with particle sizes ranging from 20-100ö¥m based on customer requirements.

Currently, eSUNMED has the kilogram-scale preparation capability for PCL, PLLA, PDLA homopolymers, and copolymers such as PDLLA, PLGA, PLCL. The company has mastered the polymerization technology for high molecular weight PLLA (intrinsic viscosity of 4.0 dL/g) and PCL (intrinsic viscosity of 2.0 dL/g), and is capable of polymerizing with different copolymer ratios and terminal group structures. Moreover, eSUNMED employs a unique purification processing technology to further improve various technical indicators of the product, ensuring that the products meet the implant-grade polylactic acid industry standard ‘YY/T 0661-2017′ and the requirements for related medicinal polymer excipients in the Chinese Pharmacopoeia.

Through research on cutting-edge microsphere emulsification and microfluidic technologies, eSUNMED can prepare emulsion droplets with controllable sizes and uniform diameters. Through the solidification process of these droplets, smooth-surfaced, high-roundness blank microspheres of PLLA, PCL, PLGA, etc., with a controllable D50 range of 10-100 ö¥m are produced. The particle size distribution is further narrowed through a special particle size grading process, achieving a span value of less than 0.7.

3D printing, as a technological revolution, is broadly and profoundly changing the way humans produce and live. eSUNMED will combine the company’s strengths in the research and development and application of polylactic acid materials, delve into related technical processes, and promote the industrialization of PLA powder printing. With material innovation, it aims to lead and drive the industry towards more efficient and sustainable production and application.

eSUNMED welcomes research institutions or enterprises with needs to contact us for product customization or new application development.

We will also continue to introduce in detail the specific applications of PLA microspheres in high-end biomedicine, and daily chemical product development, among other fields. Please stay tuned!