Post time:

Aug-03-2023

Biomedical materials are an important component of the healthcare industry. With the increasing aging of the global and Chinese population, the problem of chronic diseases that troubles people is gradually becoming prominent. In addition, with the improvement of economic development and quality of life, people’s demand for biomedical materials is also on the rise.Relying on the advantages of the parent company eSUN in the R&D and application of polylactic acid, Polycaprolactone and related copolymers for many years, eSUNMed can provide biomedical materials and equipment processing services for users in need. Previously, we introduced polylactide glycolide (PLGA) to everyone. Today, we will focus on introducing the performance and specific applications of polylactic acid copolymer PLCL in the medical field!

1.Introduction to eSUNMed PLCLPolylactic acid copolymer PLCL (co modified polylactic acid eCo PLA) is a polymer material that is copolymerized with L-lactide and other monomers. Through copolymerization modification, PLCL can effectively control the melting point, transparency, toughness, and heat resistance of polylactic acid, making up for the shortcomings of blending modification.Polylactic acid (PLA) has good biocompatibility and processing properties, but its slow degradation rate, brittle texture, and low mechanical strength limit its application. Polycaprolactone (PCL) has good biocompatibility, biodegradability and drug permeability, and has good toughness, processability and heat induced shape memory properties. However, PCL has low strength and poor hydrophilicity, which limits its application. By introducing CL segments into PLA through copolymerization modification, the crystallinity, biodegradability, and mechanical properties of the product can be adjusted, resulting in good flexibility and elasticity of the material. It can be widely used in fields such as biomaterials, 3D printing, and biodegradable biological products.

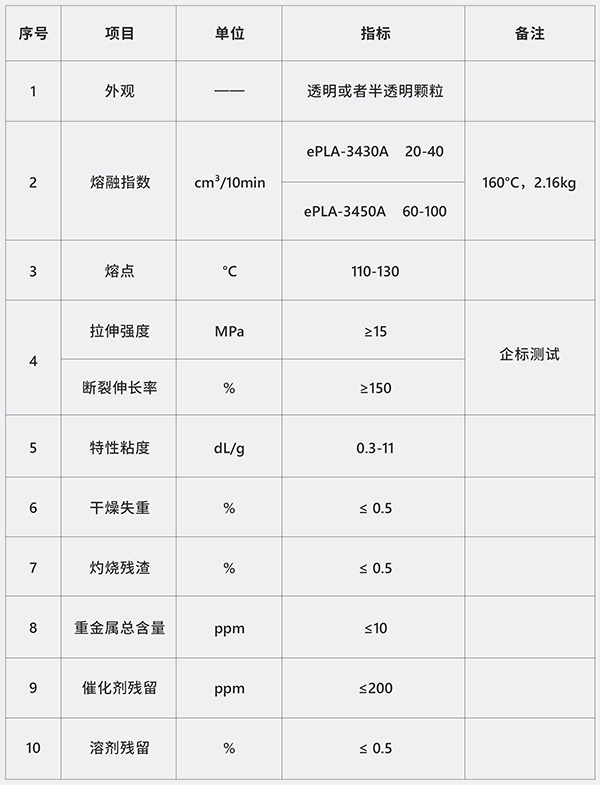

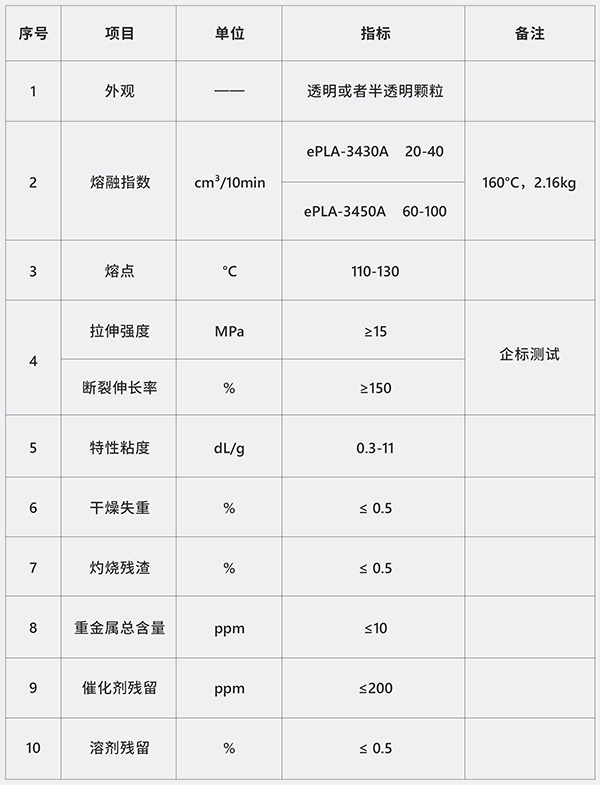

2. Physical properties indicators of PLCL

Note: Products with different molecular weights and viscosities can be prepared according to customer requirements.

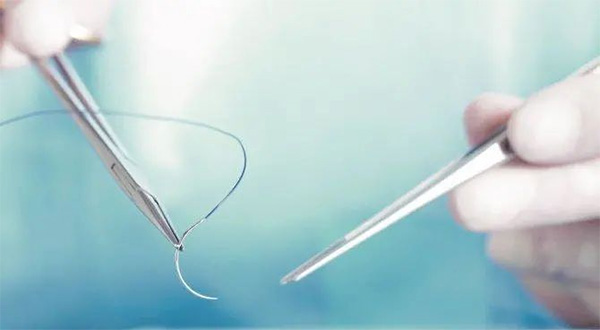

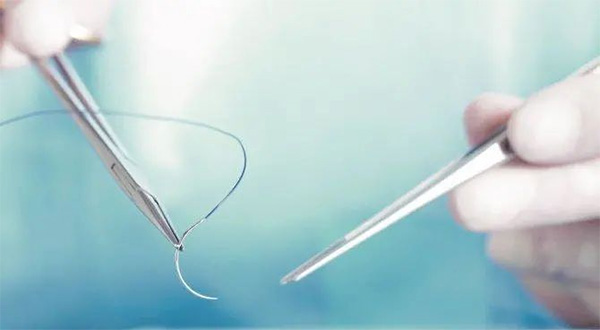

3.Application of PLCL in the field of medical devices1. Medical sutureeSUN polylactic acid copolymer eCo PLA has good biocompatibility and biodegradability, and can be used as a medical device. For example, eCo PLA3430A can be used as a medical suture, where the suture is stretched by 200% before being shaped. After the surgery, as the body temperature increases, the shape memory of the surgical line is restored, and the wound is gradually tightened and closed.

Advantages:вС† Sensitive to temperature, with good shape memory function;вС° Good biocompatibility and biodegradability.

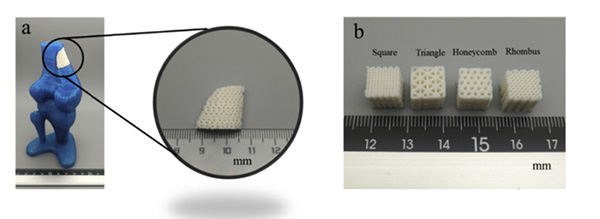

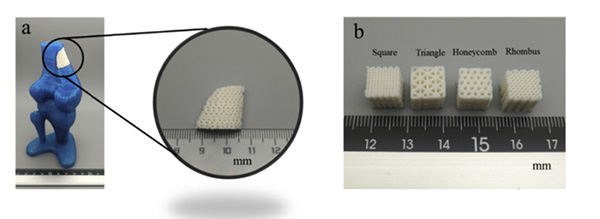

2. 3D printed bone repair bracket

PLCL has the advantages of controllable degradation rate, high flexibility, adjustable elasticity and tensile strength, and can be applied in bone tissue engineering scaffolds.

(This image is from the internet. If there is any infringement, please contact to delete it.)

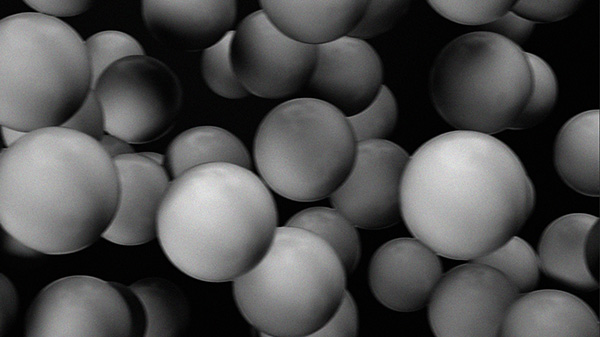

3. Drug carriersThe delayed and controlled release of drugs is very important for the treatment of tumors. By controlling the release of drugs, they can be released in a certain part of the human body for a long time and maintain a certain blood drug concentration unchanged for a period of time, thereby reducing the number of doses and avoiding uneven intake. PLCL has good mechanical strength, elasticity and flexibility. It can be prepared into drug loaded nanofibers by Electrospinning and has good slow release performance.

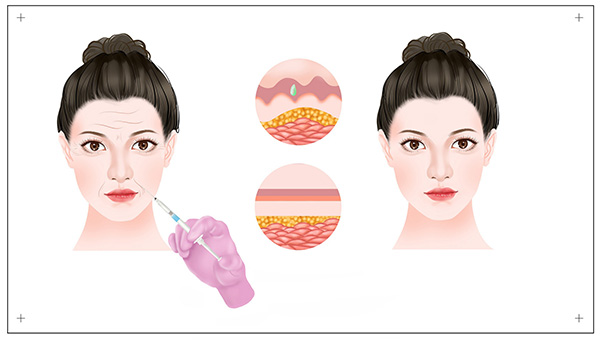

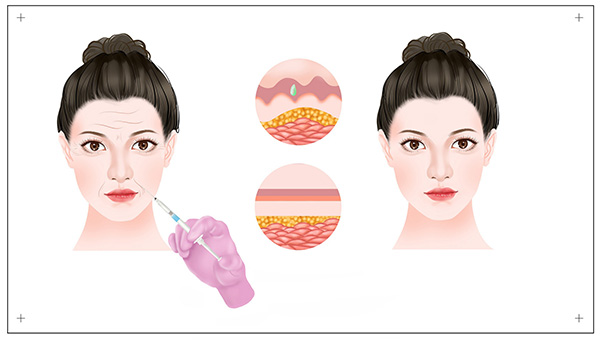

4. Micropowders

As a copolymer of L-polylactide and Polycaprolactone, PLCL balances the supporting performance and flexibility of the material, and can be prepared into micropowders for use in facial fillers, personal care cosmetics and other fields.

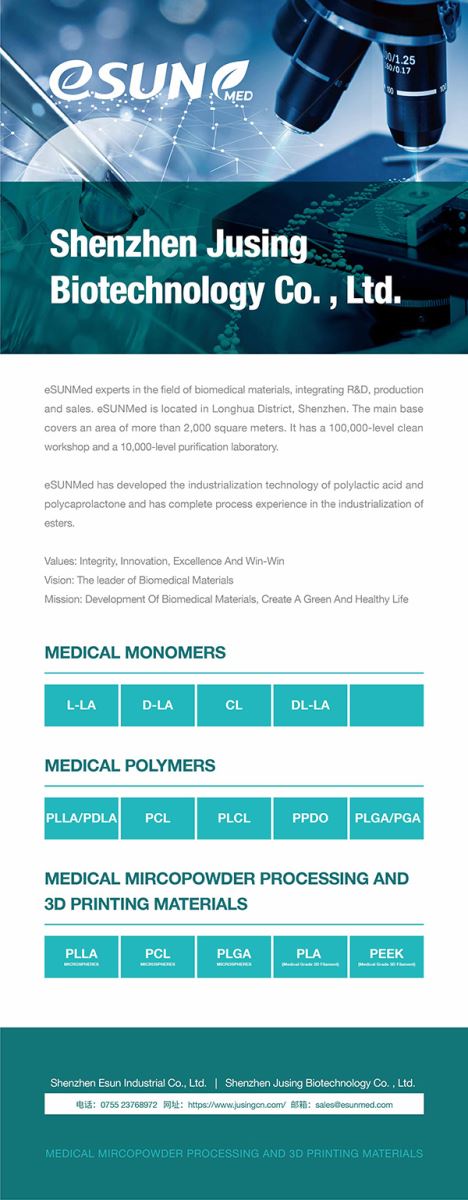

4гАБ About Shenzhen Jusing Biotechnology Co. , Ltd.¬†(eSUNMed)In March 2022, Shenzhen Jusing Biotechnology Co. , Ltd., a subsidiary of eSUN¬†was officially established. At present, eSUNMed can provide biomedical monomers, biomedical polymers, and medical 3D printing materials. At the same time, it can also provide medical processing services according to customer needs, such as medical 3D printing consumables processing, medical electrospinning processing, medical injection molding services, medical material/micropowder¬†processing, medical wire/tube/wire processing, medical 3D printing services, etc.

Previous:

From Hong Kong to Brisbane, eSUNMed and iSUN3D will appear with biomedical materials and comprehensive solutions!

Next:

eSUNMed’s Production and Customized Printing Services for Medical Implantation Grade PEEK 3D Printing Filaments