Micro Molding Services

Obviously, the term РђюmicroРђЮ suggests that micro-molding has something to do with size, but how is it defined?

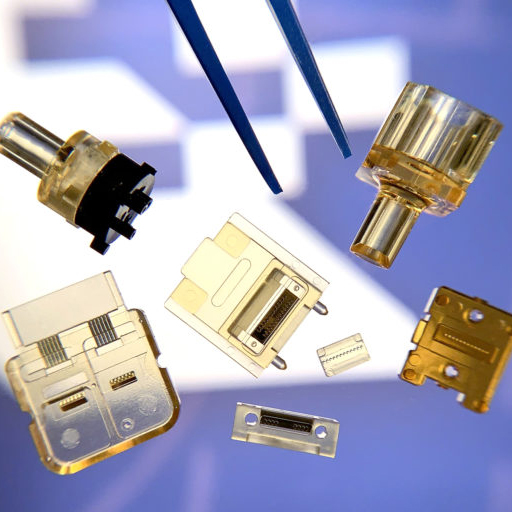

When you speak of parts that weigh less than a gram, youРђЎre in the right ballpark, but it takes more than size. ItРђЎs one thing to mold something small, itРђЎs another thing to mold it efficiently and precisely time and time again. Micro molding must be capable of producing thousands, millions, even billions of┬аparts with the same precision.

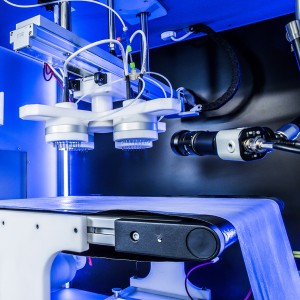

Automation & Packaging

Part handling and packaging sometimes seem like a second thought, but in many cases, itРђЎs almost as important to the process as making the part. Molding a small part is one thing. Molding it and packaging it so itРђЎs oriented in a manner thatРђЎs useful to the customer can be a challenge all on itРђЎs own.

In-house┬аcustom automation┬аand packaging can come in many forms. This can be reel-to-reel packaging, light subassemblies, lead frame die-forming and singulation, in-line inspection or a wide variety of other custom secondary processes. These added services complete the total micro-molding service and sometimes can be the difference between project success and failure.

Quality assurance┬аis imperative to any micro-molding operation. The ability to prove that parts are made to spec time and time again is where true capabilities are tested. This assurance comes in various ways.

Quality begins at the start of each project. Design for manufacturability reviews are performed to ensure the project is off on the right foot. Considerations for quality, the robustness of the process and the ability to inspect and measure happen as early in the process as possible.

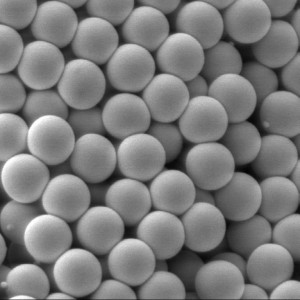

From there control plans addressing critical features, FMEA results and other quality requirements are developed. High tech and low tech measurements are used depending on whatРђЎs appropriate. Measurement plans using precision gage pins, high-resolution in-line vision systems may be employed where necessary.┬аVerification of tool dimensions as well as finished part dimensions often requires high magnification microscopic measurements.

Product handling is also a necessary consideration. Surface contamination can be at a minimum a nuisance for parts this size. Delicate features need proper processes in place to make sure the product arrives to the customer undamaged. Automation and clean room molding may be required.

Materials Best for Micro Molding

Materials Best for Micro Molding

Micro molding materials┬аcome in almost as many forms as there are ideas in the mind of a Mechanical Engineer. In the world of micro-molding, mission-critical components often require exotic or highly engineered compounds.

Materials like PEEK, PEI (Ultem®), carbon filled LCP or glass filled nylons are commonplace. Soft durometer or elastomeric resins are also prominent. Direct experience with these materials in the context of micro-molding is another part of valuable know-how needed to maximize the performance of the resin/part design combination.